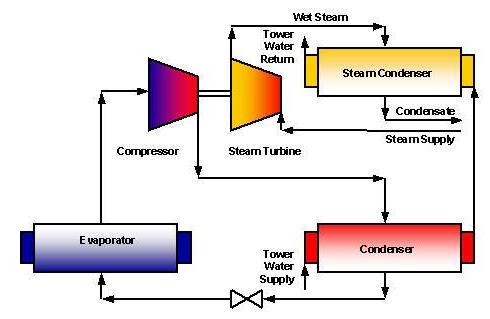

How Steam-Turbine Drive Cooling Works

Steam-turbine drive cooling uses medium pressure steam (usually 100 to 200 psig) to turn a compressor. The compressor provides the motive force for a traditional refrigerant vapor compression cycle. Similar to the absorption cooling process, useful cooling is generated in the evaporator. Heat is rejected in the refrigerant condenser to cooling water. The same cooling water is then also passed to the steam condenser to absorb the heat required to condense the steam exiting the turbine. The condensed steam is returned to the steam generating source.

Simplified diagram of a steam-turbine drive chiller